Download Documentation

GP-204 TDS

GP-204 SDS

Request a Sample

Specifications

Test

Specification

Assay:

>98.5% min

Melt Point:

201.1 – 204.0 °C

Loss on Drying:

0.5% Max

pH:

6.0 – 7.5

Chloride:

5 ppm Max

Sulfate:

15 ppm Max

Heavy Metals (as Pb):

5 ppm Max

Appearance:

Yellow Powder

Particle Size:

100% through a 20 mesh screen

Certifications & Registrations

ISO 9001:2015 is a globally recognized standard for quality management systems. It is a framework encompassing all aspects of business operations, from leadership and planning to support and performance evaluation. ISO 9001:2015 certified through DQS; BR#: 10016110 QM15.

REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) compliance is for the manufacturers and importers of chemicals in the EU. Ask us if this chemical complies with regulations and is registered with the European Chemicals Agency (ECHA), which aims to ensure a high level of protection of human health and the environment against harmful substances.

GP-204 Product Properties

- CAS #

3006-93-7

- EC #

221-112-8

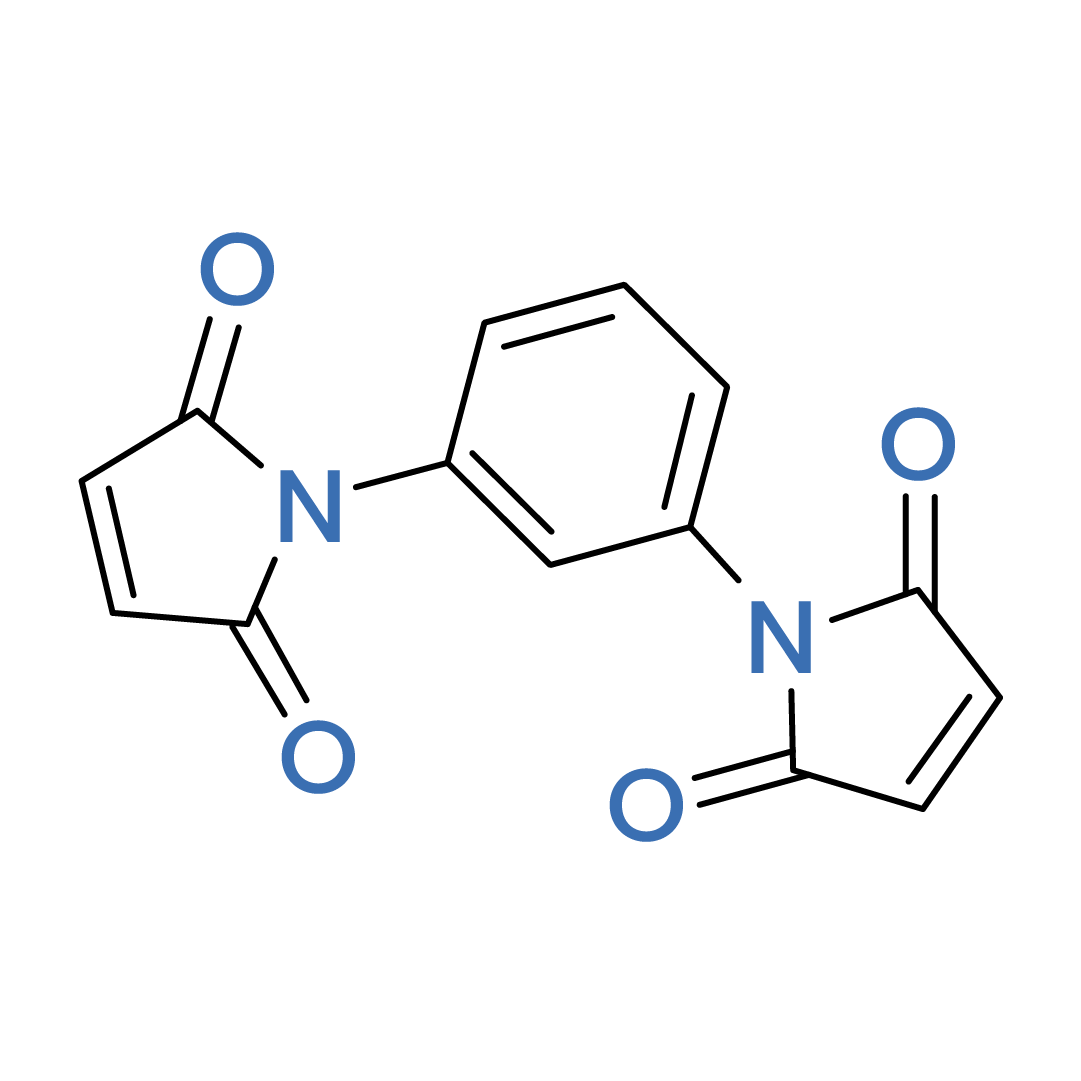

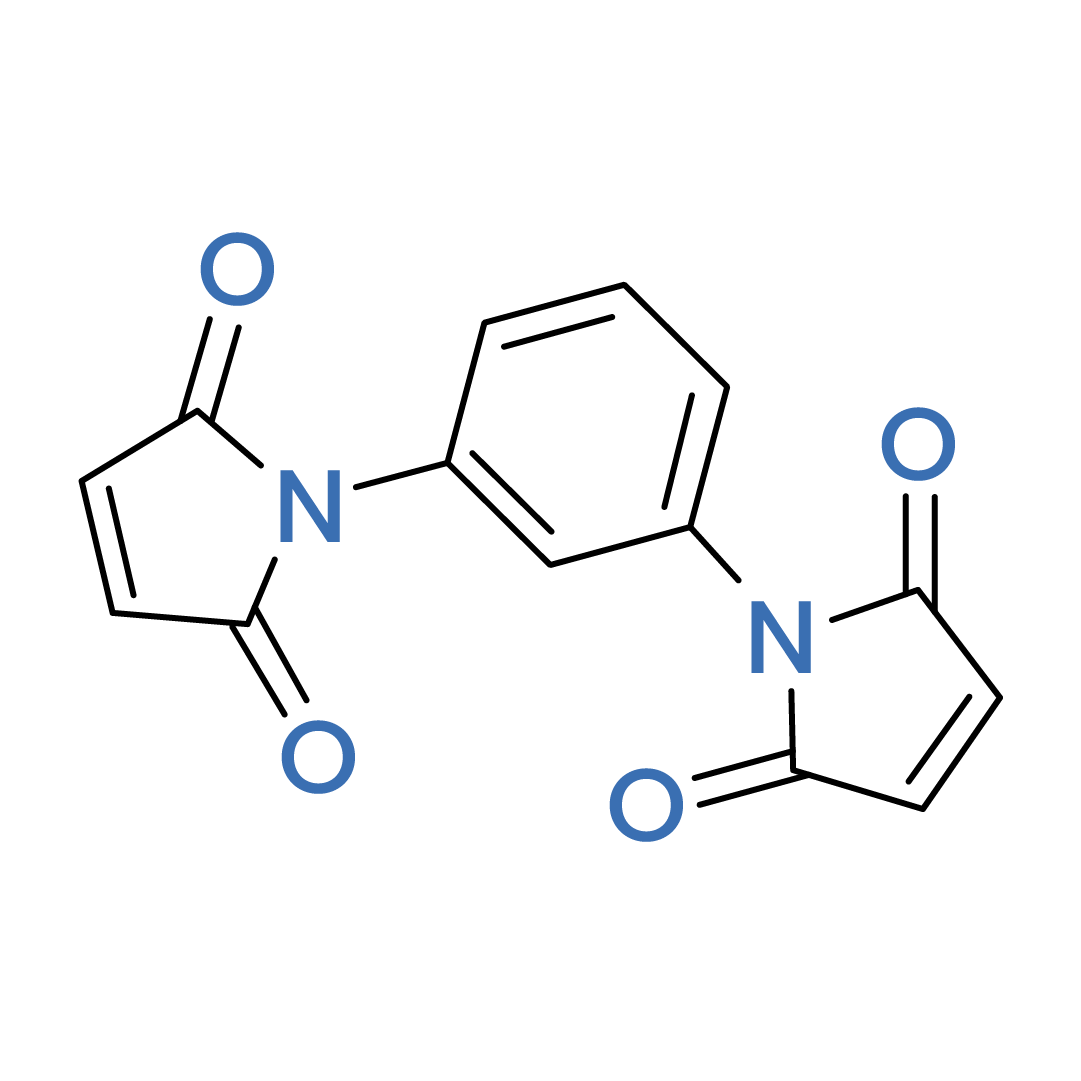

- Formula

C14H8N2O4

- Formula Weight

268.228 g/mol

- Melting Point/R

201.1 – 204.0 °C

- Physical State

Solid

- Appearance

Yellow Powder

- Categories

Rubber vulcanizing agent; rubber crosslinking agent

- Alternative Names

(Methylenedi-4,4-phenylene) bismaleimide

N,N’-m-Phenylene bismaleimide

GP-204 Oiled (N,N′-(1,3-Phenylene)dimaleimide) PDM

1,1’-(1,3-phenylene)bis-1H-pyrrole-2,5-dione

hva2;m-phdm;1,3-PDM;VANAX MBM;1,1′-(1,3;ON61250000;AKOS MSC-0044;hva-2curingagent;m-Dimaleimidobenzene;N,N’-m-phenylene bis

GP-204 (N,N’-1,3-Phenylene bismaleimide) is used to prevent reversion and improve the heat resistance, anti-aging properties and adhesion of the rubber and tire cord and vulcanized rubber modulus. (1,1’-(1,3-phenylene)bis-1H-pyrrole-2,5-dione) is a non-sulfur vulcanizing agent and primarily used in EPDM and chlorosulfonated polyethylene applications.

GP-204, Oiled (N,N′-(1,3-Phenylene)dimaleimide) PDM is a versatile chemical used in rubber vulcanization and as an adhesive additive. When added to rubber compounds, BMI reacts with the rubber chains to form cross-links. These links improve the mechanical properties of the rubber, such as its strength, durability, and heat resistance. Additionally, when combined with sulfur, BMI prevents reversion, which improves the heat resistance and reduces heat and anti-aging of the rubber. It also improves the adhesion of the rubber and tire cord and vulcanized rubber modulus. PDM, another non-sulfur vulcanizing agent, solves copper wire and copper electrical contacts' pollution problems. Typically caused by sulfur vulcanizing agents' black copper sulfide generation.

Commonly used cross-linking agent for rubber vulcanization.

When added to rubber compounds, BMI reacts with the rubber chains to form cross-links, which improves the mechanical properties of the rubber, such as its strength, durability, and heat resistance. BMI is also an adhesive additive in rubber compounds, improving the adhesion between rubber and other materials, such as metal or plastic.

PDM is a non-sulfur vulcanizing agents that solve copper wire and copper electrical contacts because of sulfur vulcanizing agent to generate black copper sulfide pollution problems.

25-gallon fiber UN rated 1G/Y/120/S fiber drum with steel top and fiber bottom.

Keep container tightly closed in a dry and well-ventilated place, store at ambient temperature.

Shelf-life: 2 years

GP-204 is a chemical that should be handled carefully. Some safety requirements should be followed when handling this chemical:

- Personal protective equipment (PPE), including gloves, goggles, and a lab coat or apron, should be worn.

- The chemical should only be handled in a well-ventilated area to avoid inhalation of fumes.

- Store in a cool, dry, and well-ventilated area, away from heat sources and incompatible materials.

- Not to be ingested or brought into contact with skin or eyes. If skin or eye contact occurs, the affected area should be flushed with water for at least 15 minutes and medical attention should be sought immediately.

- Immediately clean up Spills and use appropriate protective equipment. Follow the proper disposal procedures.

- Only allow trained personnel familiar with the chemical properties.

It is important always to follow Cymer Chemicals safety data sheet (SDS) and any other safety guidelines when handling this or any other chemical.

Reference: Cymer SDS GP-204 Oiled