Download Documentation

Di-o-allyl Bisphenol-A TDS

Di-o-allyl Bisphenol-A SDS

Request a Sample

Application

ISO 9001:2015 is a globally recognized standard for quality management systems. It is a framework encompassing all aspects of business operations, from leadership and planning to support and performance evaluation. ISO 9001:2015 certified through DQS; BR#: 10016110 QM15.

REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) compliance is for the manufacturers and importers of chemicals in the EU. Ask us if this chemical complies with regulations and is registered with the European Chemicals Agency (ECHA), which aims to ensure a high level of protection of human health and the environment against harmful substances.

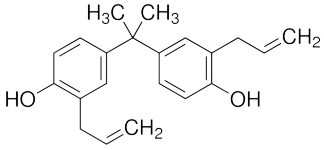

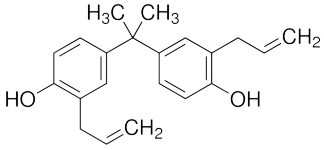

Di-o-allyl Bisphenol-A

Di-o-allyl Bisphenol-A Product Properties

- CAS #

13676-54-5

- EC #

237-163-4

- Formula

- Formula Weight

358.35 g/mol

- Melting Point/R

155-159°C/311-318.2°F

- Physical State

Powder Solid

- Categories

Aerospace Materials, Polyimide resins

- Alternative Names

2,2′-Bis(3-allyl-4-hydroxyphenyl)isopropylidene

2,2-Bis(3-allyl-4-hydroxyphenyl)propane,

4,4′-(1-Methylethylidene)bis[2-(2-propenyl)phenol]

4,4′-Isopropylidenebis(2-allylphenol)

diallyl bisphenol A is a kind of modified monomer of thermosetting resin which is mainly used in the modifying and toughening of bismaleimide resin, epoxy resin, phenolic resin etc., and it can enhance the toughness of thermosetting resin greatly. It also can be used as active diluent of thermosetting resin. The adhesion strength between metals can be further improved when used in rubber.

Diallyl bisphenol A is a modified thermosetting resin monomer with several applications. Here are some of the common uses of diallyl bisphenol A:

Modifying and Toughening Resins: Diallyl bisphenol A is used in the modifying and toughening of bismaleimide resin, epoxy resin, phenolic resin, and other thermosetting resins. When added to these resins, it enhances their toughness and impact resistance.

Actively Diluent of Thermosetting Resin: Diallyl bisphenol A can be used as an active diluent of thermosetting resin. It can reduce the viscosity of the resin and improve its processing properties.

Adhesion Strength Improvement: Diallyl bisphenol A can improve adhesion strength between metal surfaces when used in rubber.

Coatings: Diallyl bisphenol A is used as a curing agent for epoxy coatings. When mixed with an epoxy resin, it reacts with the resin to form a cross-linked network of molecules that provides mechanical strength and stability to the coating.

Composites: Diallyl bisphenol A is used as a toughening agent for epoxy resins in composite materials. Adding to an epoxy resin improves the resin's toughness and impact resistance, making it better suited for use in composite applications.

It is important always to follow the Cymer Chemicals safety guidelines and instructions when using diallyl bisphenol A in any application. This includes wearing appropriate personal protective equipment (PPE), using the correct mixing ratios, and following proper handling and disposal procedures.